Chemical Vapor Deposition (CVD) systems are essential in various industries, from semiconductor manufacturing to advanced materials development. They play a pivotal role in creating thin films and coatings that enhance the performance of products we use daily. At the heart of these intricate systems lies an often-overlooked component: the gas manifold of CVD systems. This crucial part manages gas flow, ensuring optimal deposition processes.

But what makes a gas manifold truly effective? The answer lies significantly in material selection. Choosing the right materials can influence not only performance but also longevity and reliability within your CVD system. Understanding this relationship between material choice and functionality is key for anyone involved in CVD technology or related fields.

Let’s delve deeper into this topic, exploring what gas manifolds are, why their construction matters so much, and how to choose the best materials for exceptional results.

What is Gas manifold of cvd systems?

The gas manifold of CVD systems plays a crucial role in the chemical vapor deposition process. It acts as a distribution network for various gases used during material synthesis.

In essence, the manifold directs these gases from their source to the reaction chamber. This ensures precise control over flow rates and mixture ratios, which are vital for achieving desired film properties.

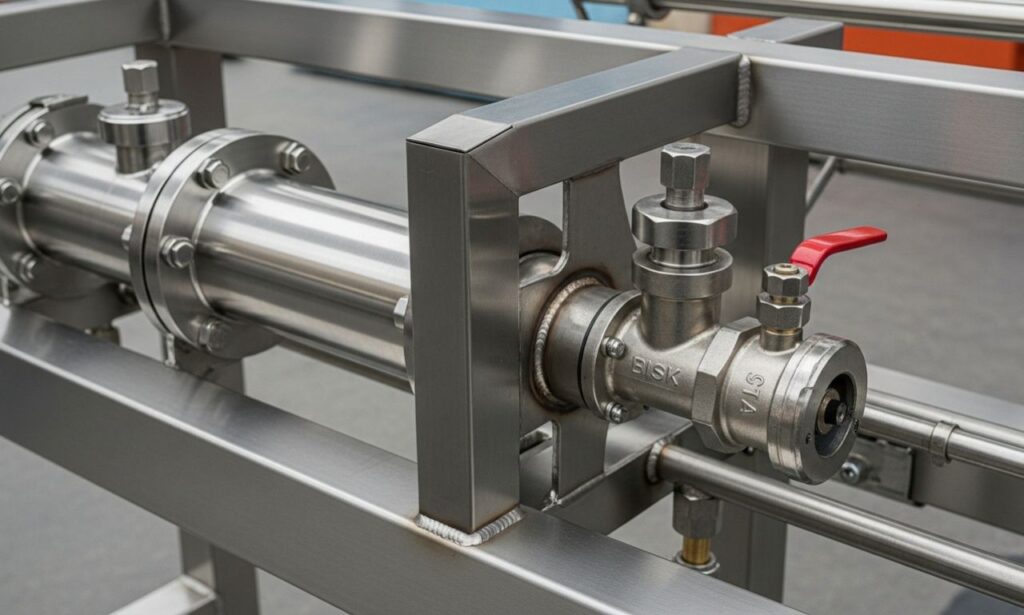

A well-designed manifold can help minimize contamination risks while maximizing efficiency. Its structure typically includes valves, flow meters, and other components that facilitate accurate monitoring.

These features enhance both safety and performance within the system. An effective gas delivery setup is essential for maintaining consistent quality in CVD applications across numerous industries.

Understanding Gas Manifolds in CVD Systems

Gas manifolds in CVD systems play a crucial role in the chemical vapor deposition process. They are responsible for distributing various gases to the reaction chamber, ensuring uniformity and efficiency.

These systems operate by mixing precursor gases before they enter the reactor. Precise control over gas flow and composition is vital for achieving desired material properties. Any inconsistency can lead to defects or suboptimal results.

The design of a gas manifold must accommodate multiple gas sources while preventing contamination. This involves managing pressure levels and maintaining purity throughout the delivery system.

In essence, effective gas management directly influences film quality and deposition rates in CVD processes. Understanding how these components work together helps engineers optimize performance and enhance productivity in semiconductor manufacturing and other applications.

Importance of Material Selection for Gas Manifolds

The selection of materials for gas manifolds in CVD systems is crucial. These components must endure high temperatures and corrosive gases while maintaining structural integrity. The wrong choice can lead to costly failures.

Materials influence not just durability but also the chemical compatibility with the gases involved. A mismatch can compromise performance and safety, resulting in unplanned downtime or even hazardous leaks.

Additionally, the weight and thermal conductivity of the material play vital roles. Lightweight options improve handling and installation, while good thermal conductors help regulate system temperatures effectively.

Investing time in selecting appropriate materials ensures longevity and reliability in gas manifold operations. It’s an essential factor that directly impacts efficiency, productivity, and overall system performance.

Common Materials Used for Gas Manifolds

When it comes to gas manifolds in CVD systems, materials play a vital role. Stainless steel is a popular choice due to its excellent corrosion resistance and durability. It can withstand harsh environments while maintaining structural integrity.

Another common material is aluminum. Lightweight yet strong, aluminum offers good thermal conductivity. This makes it suitable for applications where heat dissipation is crucial.

Teflon is also used for specific scenarios, particularly when handling reactive gases. Its non-stick properties prevent contamination and ensure the purity of the process gas.

Sometimes manufacturers opt for special alloys designed to resist high temperatures and corrosive chemicals. These custom solutions can enhance performance significantly.

Each material has unique advantages tailored to different operational needs, making careful selection essential for optimal system functionality.

Factors to Consider When Choosing Materials for Gas Manifolds

When selecting materials for gas manifolds in CVD systems, several factors come into play. First, compatibility with gases is crucial. Different gases can react differently with various materials; hence understanding the chemical properties is essential.

Temperature resistance is another vital consideration. Manifolds often operate under high temperatures, so choosing a material that maintains integrity at these levels prevents failures and leaks.

Pressure ratings also matter significantly. The manifold must withstand the operational pressures without deforming or cracking. This ensures consistent performance over time.

Corrosion resistance cannot be overlooked either. Exposure to reactive gases necessitates using materials that resist degradation and prolong lifespan.

Manufacturing processes impact material choice as well. Some materials are easier to work with while others may offer superior performance but require more complex handling techniques.

Benefits of Using High-Quality Materials for Gas Manifolds

Using high-quality materials for gas manifolds significantly enhances the performance and safety of CVD systems. Superior materials resist corrosion, ensuring longevity and reducing maintenance costs over time.

Durability is another key advantage. High-grade components can withstand extreme temperatures and pressures, which are common in chemical vapor deposition processes. This resilience translates to fewer failures and interruptions in operations.

Moreover, high-quality materials contribute to better gas flow efficiency. They minimize leaks, allowing for optimal control over gas distribution within the system. Enhanced precision leads to improved film quality on substrates.

Investing in top-notch materials reinforces compliance with industry standards. This not only safeguards equipment but also protects workers from potential hazards linked to poor material choices. The result is a more reliable and efficient CVD process overall.

Maintenance and Care Tips for Gas Manifolds

Regular inspections are crucial for maintaining the functionality of gas manifolds in CVD systems. Check for signs of wear, corrosion, or leaks at least once a month.

Cleaning is equally important. Use appropriate solvents to remove any buildup that might obstruct gas flow. Avoid abrasive materials that can damage the surface.

Ensure all connections are tight but not overtightened; this prevents unnecessary stress on joints and reduces the risk of leaks.

Document your maintenance schedule to track any issues over time. This record can help identify patterns that may require attention.

When replacing parts, opt for high-quality components designed specifically for your system’s requirements. Quality replacements enhance performance and longevity.

Always follow manufacturer guidelines for care and maintenance protocols tailored to your specific gas manifold model to ensure optimal operation.

Conclusion

The gas manifold of CVD systems plays a critical role in ensuring the successful operation of chemical vapor deposition processes. From delivering gases uniformly to maintaining precise flow rates, its importance cannot be understated. Selecting the right materials for these manifolds is essential for achieving optimal performance and longevity.

Choosing high-quality materials leads to enhanced durability and reliability while minimizing contamination risks. This selection process must consider various factors, including compatibility with gases used, temperature resistance, and ease of maintenance.

With proper care and attention, gas manifolds can maintain their efficiency over time. Regular inspections and appropriate cleaning schedules will contribute significantly to extending their lifespan.

Investing in superior materials not only facilitates better results but also ensures a smoother operational experience within CVD systems—ultimately leading to improved quality in semiconductor manufacturing or any other applications that rely on this technology.